Alışveriş sepetiniz boş!

Plastisol ink is essentially liquid plastic. Plastisol is the dominant ink of choice as it is user friendly. It does not evaporate. In other words, it is extremely easy for the manufacturing company to implement. It doesn't have to move fast. During the production (Screen Printing process), it can pause the production at any time. When a lunch break is given, the ink never gets dry or hardened. Of course, there is no blockage in the printing sieves during the printing process. Clogging of fine and very small holes of silk is a serious problem. Plastisol ink does not cause this problem. So is that all?

Plastisol also has a high opacity. The ink covers the fabric color well and can cover mistakes easily. In fact, you can easily cover an error with a second pass. As a result of these reasons, screen printing does not require great mastery and attention in the application process.

Well, if plastisol ink offers so many conveniences, why would you want to use water-based ink?

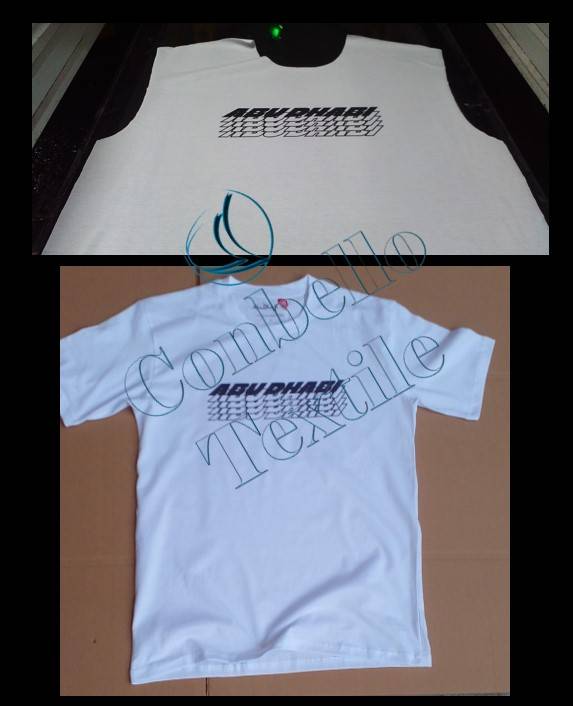

Water-based ink is an ink that is increasingly demonstrating its unparalleled superiority in the world of screen printing. Water-based ink leaves a thin, soft, flexible ink layer on clothing. Because you don't use any toxic chemicals, you can reduce your eco footprint. As Conbello Textile, all of our screen printing systems are based on the use of fully organic water-based ink. Considering the materials and energy used in the production of water-based ink, water-based ink undoubtedly surpasses plastisol ink. One of the most important elements that makes water-based ink much more environmentally friendly than plastisol is that the water-based ink on the fabric is recyclable. Unfortunately, this is not the case at all with Plastisol ink. If the company that will manufacture your products has the necessary equipment to print water-based inks, of course, using water-based inks is an excellent idea.

Printing with water-based inks is not as easy as you might think. You need to be constantly alert. Since water-based inks contain water, the ink starts to evaporate when exposed to air. If you take a break and do not take the necessary precautions, you will encounter very serious problems.

First, you need to evaporate all the water. You can't cure the ink if you don't evaporate all the water. When all the water has evaporated, the remaining layer of ink (resins in the ink) must reach the recommended curing temperature and hold at that temperature for a minimum of 15-20 seconds. For Colin, it takes one minute and forty-five seconds in a compressed air conveyor dryer to evaporate and properly cure a water-based print. Definitely not the simplest process.

Water-based ink is smoother than plastisol.

Plastisol ink is thicker than water-based ink. It will rise slightly more on the shirt than water-based ink will, adding more dimension to the print. Plastisol ink is also harder than water-based ink. If you crumple a garment, the plastisol ink will feel tougher.

If a client is looking for a super smooth print, water-based ink is the way to go. A customer looking for a super glossy print? Time to remove the plastisol ink.

Plastisol is an oil-based PVC ink system. There is no water in Plastisol. A plastisol print is a layer of solidified plastic that sits on top of the fabric. So, imagine that you completely covered the fabric, something like this.

There are important reasons to use water-based ink. Many people like the soft touch of water-based prints.

If you want to print more environmentally friendly, water-based inks come before plastisol inks in this area.

It seems difficult and expensive to implement greener practices, but this is not the case.

Water-based ink has a softer touch and soft feel. Water-based prints can feel so soft that it can feel like part of a shirt.

Water-based ink has better breathability. Because water-based inks are absorbed more deeply into the fabric, most of the gaps between the fibers are left open. This gives water-based prints more breathability than Plastisol print, which tends to close these small gaps.

Recently, there has been a huge push towards “eco-friendly” production methods, governed by the Consumer Product Safety Information Act (CPSIA), as well as by some major brands, in an effort to reduce the use of PVC and completely ditch phthalates (an even more toxic polymer). That's why key players in the industry are marketing water-based inks as a solution.

Longevity: Water-based prints last the life of the garment with no signs of cracking or peeling over time.

Feel it: Water-based ink will leave an imprint on your shirt that is much softer and more breathable than any other type of ink. You literally can't even feel the ink on the shirt, as the ink dyes the fabric of the shirt.

Water-based ink is a higher quality ink that requires serious training to use. Because inks react differently with every t-shirt, getting the right colors and opacity requires a deep knowledge of ink and fabric type.

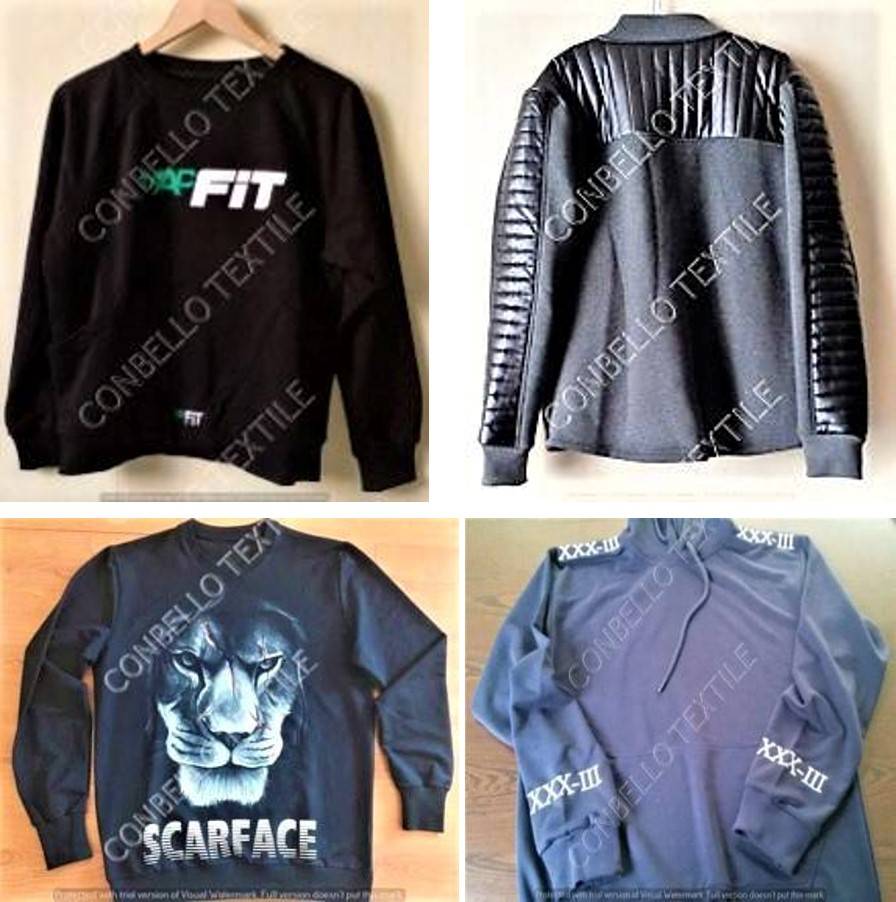

As a result, when you work with Conbello Textile, you will have the comfort of knowing that there will be no questions left in your mind.

It will be useful for you to review our related pages below.

Support for startup Fitness clothing brands