Alışveriş sepetiniz boş!

Fabric selection in sportswear is a very sensitive issue, and it is very important which fabric type and weight will be used in which product. The most serious mistake we see in start-up or mid-size sportswear brands is that they only focus on cheap prices. Although it is not a very nice term, it should not be forgotten that free cheese can only be found in a mousetrap. Of course, this issue does not only end with your choice of fabric. You should know much more important and vital technical information about the fabric to be used. !

As Napoleon said, if there is no gunpowder (you can think of it as ammo) there is no point in continuing the war. If you take active wear and sportswear seriously and want to be a permanent and growing brand, you have to know that one of your most important arsenals is fabric.

We tried to briefly summarize the points that should be considered in the selection of fabrics to be used in products such as T-shirts, Athletes, Hoodies, Polos, Leggings or Sports Bras as sportswear.

Fabric touch and knitting/weaving systems are also crucial to the excellent quality of your sportswear product.

Your fabric should definitely not fade after washing. For this, a special color fixation application is made during the manufacture of the fabric. Much cheaper clothing products can be produced using poor quality fabrics. However, your cheap sportswear products are such a sensitive issue that it may cause your business to go bankrupt. Or at best, your initial investment will go to waste. Of course, this is a very expensive trial method.

Yes, although it may seem that it has nothing to do with the fabrics used in fitness clothing, it actually does. And we think you should definitely read it to grow your brand. Because you will face the facts and you will see the way out more clearly.

How to create a successful sportswear brand?

How do I start a fitness clothing brand

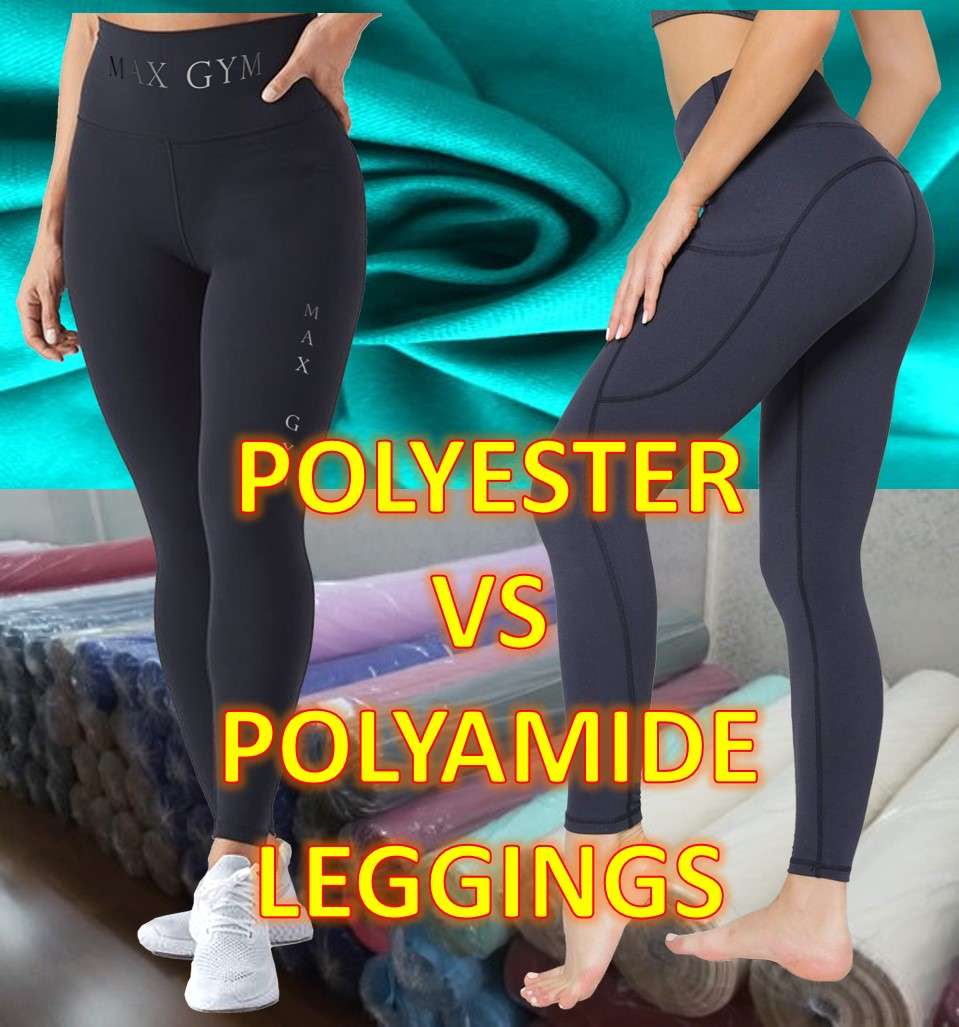

As Conbello Textile, we use approximately 150 types and sub-types of fabrics according to the purpose of use in sportswear. There is absolutely no clear answer to this question. For example, polyester or polyamide fabric, which is often recommended in many places to be used in leggings and sports bras. Really ?. Definitely not. As Conbello Textile, of course, we use polyester and polyamide fabrics of the highest quality and in all weights. However, we also use original cotton fabric in the manufacture of leggings and sports bras. The leggings and other sportswear products we manufacture from cotton fabric have extremely natural and breathable properties. Cotton fabric has an incredible advantage over synthetic fabrics (polyester, polyamide fabric). They do not contain BPA (Bisphenol-A), which is a toxic chemical. Read detailed information about BPA here.

Fabrics such as Polyester, Polyamide, Cotton, Tencel, Viscose, Bamboo can be preferred. However, do not forget the critical point. It is not what is written on the label of the fabric, but what the fabric actually is. For example, when we test Bamboo fabrics, we see that most of them are a mixture of Bamboo and viscose fabrics. Conbello Textile uses original Anti-bacterial Bamboo fabric fabric.

What fabric is sportswear? / Fabric types such as Cotton, Polyester, Viscose, Tencel can be preferred, but the most important point is that all finishing processes are completed during fabric production. In addition, fabric with different elastane ratio should be used according to the intended use of the sportswear product. In the meantime, what weight the fabric should have in the relevant sportswear product should be calculated clearly and accurately. Conbello Textile will give you technical advice on this and all matters.

Our customers who have had painful experiences with their first investments

We have clients that we have worked with for nearly 25 years since the beginning of their business. Therefore, we gain many new customers thanks to the recommendations of these old friends.

Many of our customers, who came with the advice of our old customers or found us from scratch, are people who have experienced bitter experiences above. Many of our customers have lost their initial investment, thanks to companies that are inexperienced or look at sportswear manufacturing as just making money.

A poor quality and cheap fabric starts to deteriorate in the first washes, even after the product has been worn for a while, regardless of the printing system you apply on it. The color of the print applied to the fabric will fade quickly. This color fading/deterioration, which can be seen very quickly in print, ultimately leads to wastage of the entire product!

Of course, these are just the beginning. When we start working together, you will realize that the subject of fabric selection is very deep and important.

It will be useful for you to review our related pages below.

Support for startup Fitness clothing brands